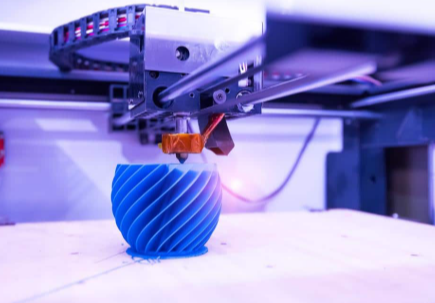

3D printing technology has significantly expanded its role beyond mere rapid prototyping. Industries such as automotive, aerospace, and healthcare are now harnessing its capabilities to create complex, lightweight components and customized medical devices. This shift reflects a broader trend towards additive manufacturing, which emphasizes design freedom and efficiency. As companies adopt these innovations, the implications for production processes and product development are profound. What might this mean for the future of manufacturing?

The Evolution of 3D Printing Technology

The journey of 3D printing technology has transformed from a niche experimental process into a pivotal force in various industries.

Historical milestones, such as the development of stereolithography and selective laser sintering, laid the groundwork for subsequent technological advancements.

These innovations have expanded the capabilities of 3D printing, fostering creativity and enabling unprecedented freedom in design, manufacturing, and prototyping across diverse sectors.

Read more: How AR Glasses Could Replace Your Phone

Industry Applications Transforming Production

Numerous industries are embracing 3D printing to revolutionize their production processes, leading to significant advancements in efficiency and innovation.

Automotive innovations utilize additive manufacturing for creating complex components, enhancing design flexibility and reducing weight.

Similarly, medical breakthroughs are achieved through custom prosthetics and implants, tailored to individual patients.

These applications exemplify how 3D printing is transforming traditional manufacturing paradigms across diverse sectors.

Future Trends in Additive Manufacturing

As industries increasingly adopt 3D printing to enhance production capabilities, the future of additive manufacturing appears poised for remarkable evolution.

Innovations will likely focus on sustainable materials, enabling eco-friendly practices in digital fabrication. Enhanced technologies are expected to streamline workflows, reduce waste, and expand design possibilities, fostering a more agile and responsive manufacturing landscape that prioritizes both efficiency and environmental responsibility.

Conclusion

In conclusion, 3D printing has transitioned from a prototyping powerhouse to a pivotal player in diverse industries, driving dynamic developments and design diversity. With its unparalleled potential for personalization and precision, additive manufacturing is poised to propel productivity and innovation to new heights. As technology continues to transform, the future of 3D printing promises to be a landscape of limitless possibilities, fostering a flourishing fusion of function and form in manufacturing practices across the globe.